Driving Global Readiness in Indian Pharma: ZETA India’s Roadmap for Annex 1 Compliance and FDA’s Aseptic Guidance

India’s pharmaceutical sector stands at a global inflexion point. Renowned as the world’s pharmacy, the nation’s sterile manufacturing segment is experiencing a surge in international demand, particularly as exports to regulated markets, such as the European Union, the United States, and beyond, continue to rise. In this transformed landscape, the EU’s revised GMP Annex 1 and the FDA’s Aseptic Guidance are no longer just “Western” regulatory protocols. They have become gatekeepers for every Indian manufacturer aiming to deliver injectables, vaccines, and biosimilars worldwide.

Both Annex 1 (EU) and the FDA Aseptic Guidance (USA) ensure the sterility of medicinal products, but they apply to different markets and scopes. Annex 1 covers both aseptic processing and terminal sterilisation, while the FDA guidance focuses only on aseptic processing. Both require strict sterile manufacturing practices and a contamination control strategy.

The EU’s Annex 1, updated in 2023, has redefined global expectations for sterile pharmaceutical manufacturing. Its standards, once primarily European, are now the gold benchmark for any company, especially Indian manufacturers supplying sterile medicines to advanced markets. More than a set of GMP rules, Annex 1 demands a continuous, risk-based approach to quality, centred on a comprehensive Contamination Control Strategy. This roadmap isn’t just about regulatory approval; it is about embedding science-led controls that protect product quality and patient safety throughout the entire process. For India’s pharmaceutical sector, aligning with these regulatory requirements is both a path to global competitiveness and a statement of leadership in delivering safe, high-quality therapeutics to the world.

Annex 1: What It Means for Indian Manufacturers

The overhaul of EU GMP Annex 1, which took effect in August 2023, is ushering in the most substantial changes to sterile product manufacturing in more than 20 years. Its reach is truly global, embracing not only European regulators but also the US FDA, WHO, and Indian authorities, who recognise its best-practice benchmarks for sterility assurance. Critically, any pharmaceutical product destined for the EU must now meet these requirements, meaning Indian API, formulation, and contract manufacturers need to align their facility design, risk management, and production diligence to match the world’s highest standards.

This regulatory transformation centres on Contamination Control Strategy (CCS), which requires proactive, science-based controls for all sterile processes, and elevates the roles of quality risk management (QRM), documentation, and cross-departmental collaboration. For the Indian pharmaceutical industry, this means bridging legacy practices with next-generation process engineering, digital validation, and robust personnel training.

India’s Competitive Edge: Adopting “Quality by Design” for Global Markets

ZETA India is at the forefront, helping Indian clients embed the “Quality by Design” (QbD) philosophy across all aspects of bioprocess and cleanroom infrastructure. Indian pharmaceutical companies are known for their operational agility and innovation. By combining these strengths with ZETA’s expertise in advanced facility design, digital automation, and global compliance, companies can accelerate their pathway to both EU and US market entry.

Instead of relying solely on end-product inspection, Indian pharmaceutical clients are increasingly interested in integrating QRM into every phase of plant, equipment, and process development. ZETA’s solutions are tailored for India’s scale, capacity, and complexity, thereby ensuring comprehensive risk reviews, CAPA planning, and future-proofed engineering that withstand both Indian GMP and global audits.

Real-Life Impact: Modernising Sterile Filtration in Indian Factories

Implementation is often where many Indian businesses hit regulatory bottlenecks. The interpretation of these regulatory requirements can be daunting given their scope. Even India’s CDSCO and state FDAs now expect international standards from facilities exporting sterile products.

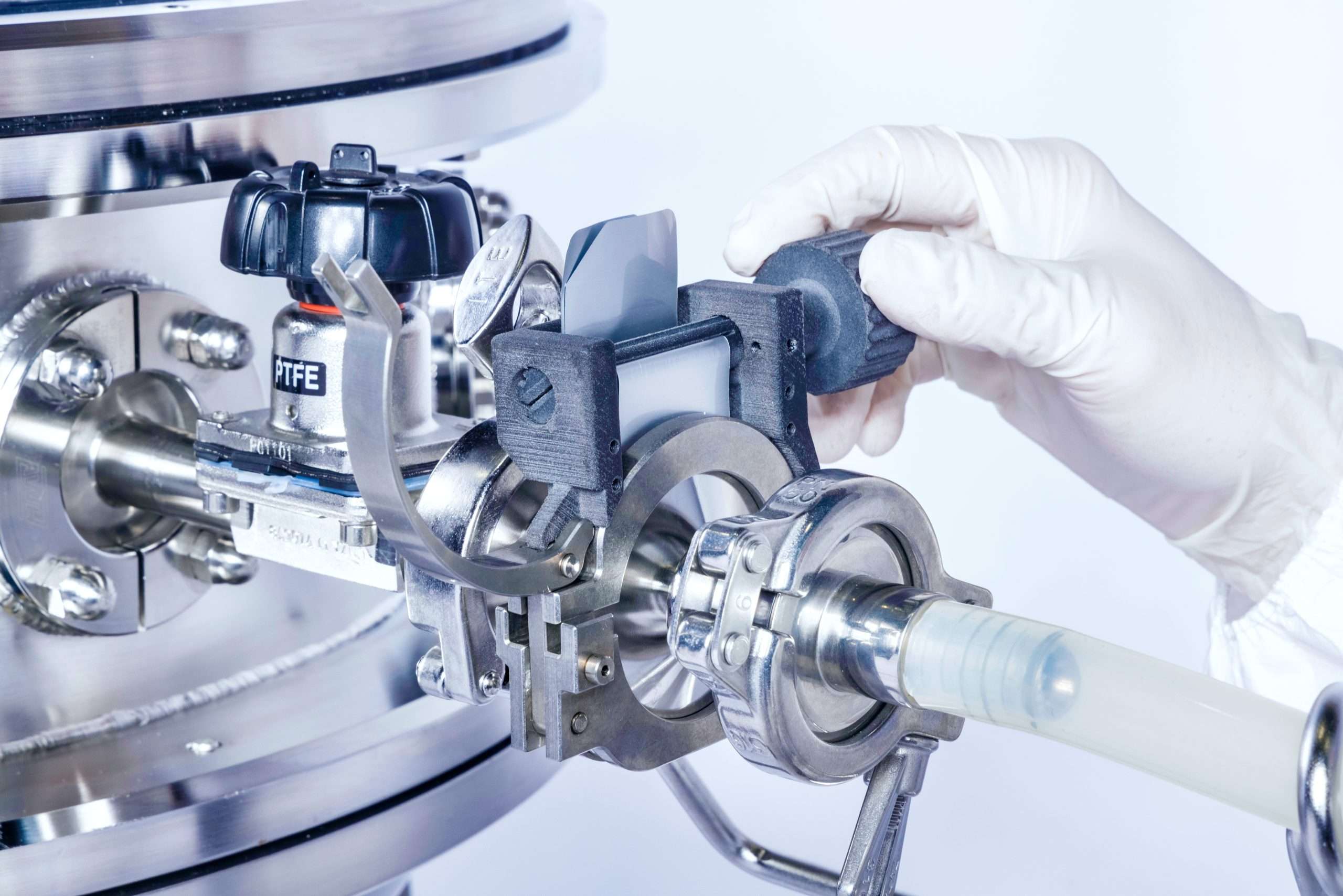

A recent ZETA feasibility project in a large-scale sterile fill-finish unit echoes challenges familiar to Indian manufacturers – integrating sterile filtration at the point-of-fill, adapting existing lines for process reliability, and rolling out integrity-tested, single-use systems. ZETA’s phased approach reduces production downtime and uses robust risk analysis (including FMEA) to identify and close gaps systematically.

For Indian facilities managing diverse portfolios, from large-volume parenterals to niche biosimilars, ZETA’s techno-commercial expertise is invaluable. Their ability to weigh options between in-line stainless assemblies, mobile single-use systems, and laminar flow adaptations enables Indian pharmaceutical plants to pick the ideal solution for speed, cost, and certifiability.

Managing the Indian Scale: Accelerating Facility Upgrades and Cleanroom Projects

One hallmark of the Indian industry is its speed and scale. ZETA responds with its comprehensive EPCMV (Engineering, Procurement, Construction Management, and Validation) model, offering Indian manufacturers a single point of control partner for facility upgrades, process automation, and cleanroom retrofits. By overseeing the entire scope, from initial risk assessment and regulatory submission through to validation and handover, ZETA eliminates project delays and multiplies value in India’s high-throughput environment.

Moreover, with Indian pharma’s rapid adoption of digital transformation and sustainability, ZETA’s end-to-end solutions for digitalisation and decarbonization prepare plants for both global regulations and local environmental mandates.

Looking Ahead: India’s Global Pharmaceutical Future

More than ever, Indian pharmaceutical and biopharmaceutical firms face a dual imperative: satisfying global regulators, such as the EU EMA and US FDA, while remaining nimble to meet the needs of India and emerging markets. ZETA India remains the ideal partner, marrying deep global regulatory insights and state-of-the-art engineering to Indian ingenuity and ambition.

As India advances in the global value chain for sterile medicines, investing in advanced CCS frameworks, digitised quality systems, and world-class facility engineering is non-negotiable. With ZETA’s support, Indian pharma not only meets these global regulations but also defines the new gold standard for quality, safety, and patient trust in every international market.