Fermentation is the backbone of contemporary biopharmaceutical production, enabling manufacturers to create a wide range of products, from life-saving vaccines to high-value APIs and recombinant proteins. For production and project managers, mastering the principles of fermentation extends well beyond the science – it’s about delivering transformative therapies efficiently, safely, and at scale.

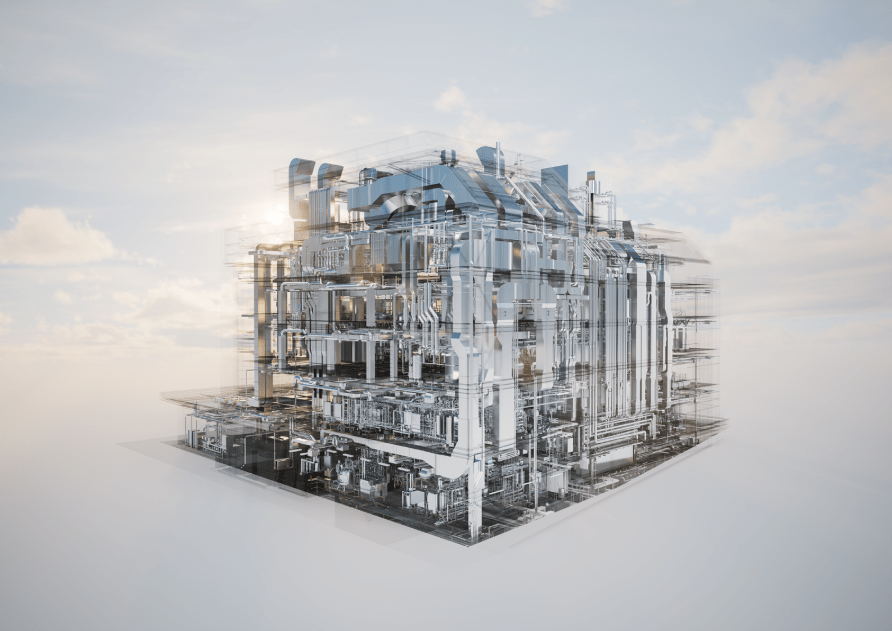

Industry leaders like ZETA engineer industrial fermenters and bioreactors to deliver optimal cell growth, maximise product yield, ensure consistent throughput, and drive uncompromising quality—the core principles that shape the future of pharmaceutical manufacturing.

Key Applications of Fermentation Technology in Pharma and Biopharma

Fermentation technology is integral to multiple critical areas within the pharmaceutical and biopharmaceutical industries.

- Antibiotic production: Fermentation remains pivotal for the large-scale synthesis of antibiotics, enabling controlled microbial growth and optimised yields.

- Recombinant protein expression: Engineered hosts (bacteria, yeast, or mammalian cells) cultivated in fermenters are used to produce monoclonal antibodies, enzymes, and hormones to precise standards.

- Vaccine manufacturing: Fermenters allow robust propagation of viral vectors and cell cultures, underpinning the rapid response capability required for pandemic preparedness.

- API synthesis: Many small-molecule APIs and intermediates are derived from microbial fermentation, providing manufacturers with a scalable and repeatable pathway for high-purity production.

- Biosimilars and personalised therapies: Fermentation is central to the cost-effective manufacturing of biosimilars, supporting reproducibility and regulatory compliance.

In every application, fermentation delivers consistency, scalability, and the ability to adhere to regulatory requirements—key to achieving a competitive advantage in today’s complex landscape.

The Drivers of Pharmaceutical Success

Across the varied applications listed above, operational success is fundamentally driven by three core pillars: achieving optimal yield, maximising throughput, and ensuring uncompromising quality. Each aspect plays a crucial role in realising effective, scalable, and compliant production processes that meet the stringent demands of modern health care and regulatory environments. In the sections that follow, we will explore how yield, throughput, and quality are shaped and enhanced through advanced fermentation systems and process expertise.

- Yield: The efficiency engine

Fermentation yield defines how much of the desired product is generated from a given quantity of raw material. Achieving high yields in pharma fermentation depends on:

- Optimised bioreactor design for uniform mixing, temperature control, and oxygen transfer

- Smart strain selection and breeding, often leverage advances in genetic engineering to improve productivity and stress resistance.

- Precise monitoring of process variables such as pH, nutrient supply, dissolved oxygen, and agitation throughout the run

- Integrated data analytics and automation (as seen in ZETA’s Pharma 4.0 initiatives) to enable real-time adjustments

Recent technologies, such as predictive bioreactor characterisation for upstream control and inline buffer conditioning for downstream flexibility, enable manufacturers to optimise process conditions across the production chain.

- Throughput: Scaling up safely

Throughput in fermentation refers to the volume of product produced per unit of time, which is crucial for meeting market demand, especially for large molecules and biopharmaceutical APIs. Key throughput drivers include:

- Facility engineering to support seamless scale-up from bench to industrial scale.

- Modular, automated fermentation systems that allow quick changeover and multiproduct flexibility.

- Efficient upstream solutions, such as ZETA’s suspended skid design, reduce downtime, streamline process transfer, and enable rapid facility cleaning.

- Use of single-use and hybrid stainless steel systems for easy switching between batches and reduced risk of cross-contamination.

- Quality: Ensuring consistency and compliance

Quality in pharmaceutical fermentation goes beyond producing high-purity products; it encompasses batch-to-batch reliability, regulatory compliance, and process robustness. Quality drivers involve:

- Advanced bioreactor controls and engineered vessels designed for sterility and GMP compliance.

- Real-time process analytics and predictive tools to anticipate deviations and maintain optimal conditions.

- Lifecycle management approaches – from process simulation to maintenance digitisation, for long-term reliability.

Industry best practices emphasise validating process parameters at all scales, thorough documentation, and integration of digital twins and simulation for proactive troubleshooting and continuous improvement.

With our expertise in bioreactor design and in the customisation and integration of single-use technology, we excel at delivering solutions designed for precise control, rapid scale-up, and advanced quality assurance—whether your process relies on stainless steel, single-use systems, or a hybrid approach.

Choosing the Right Fermentation Technology

For production and project managers, the choice of fermentation technology is a strategic decision that determines operational success. Factors to consider include:

- Scalability: Modular platforms allow seamless expansion without compromising process integrity.

- Process flexibility: Facility-fit solutions (including ZETA’s bespoke designs) enable swift product changeover and adaptation to new regulatory demands.

- Integration: Smart systems for control, cleaning, and monitoring ensure scalability and reproducibility from laboratory to manufacturing floor.

- Compliance and reliability: GMP-compliant equipment, combined with predictive digital lifecycle management tools, ensures robust quality control and audit-readiness.

Investing in the right technology transforms manufacturing agility, reduces risk, and futureproofs operations in a fast-evolving sector.

Empowering Pharma’s Next Generation

As new molecules and therapies emerge, so too do the demands on biopharma manufacturing. Modern fermentation technology is continually advancing, driven by innovative equipment designs, data-driven production, and robust automation platforms. By understanding and applying the principles of fermentation technology, and selecting the right partners and equipment, production and project managers can deliver results that set their organisations apart. Firms like ZETA lead the charge, offering reliable solutions designed for efficiency, scalability, and uncompromising quality, helping pharma companies meet the needs of patients and markets, now and in the future.