When you need high gas–liquid contact in a tight footprint, a tower fermenter can be a smart way to unlock performance without defaulting to ever-larger stirred tanks. This tall tower format is essentially a vertical column vessel: height increases bubble contact time, changes hydrostatic pressure, and can improve oxygen availability for certain aerobic fermentation processes. When it’s engineered well, the result is a reliable, solution-oriented fermentation platform—especially where floor-space, long-run robustness, and fewer moving parts are part of the decision.

A tower fermenter is often used as a non mechanically stirred fermenter (i.e., without an internal agitator shaft), relying on gas-driven mixing rather than a motor-driven stirrer. Below, you’ll find what it is, how it works, key design building blocks (sparger, cooling jacket/coil, circulation), where it’s used in industry, and how to choose a tailor-made system for your process window.

What is a tower fermenter?

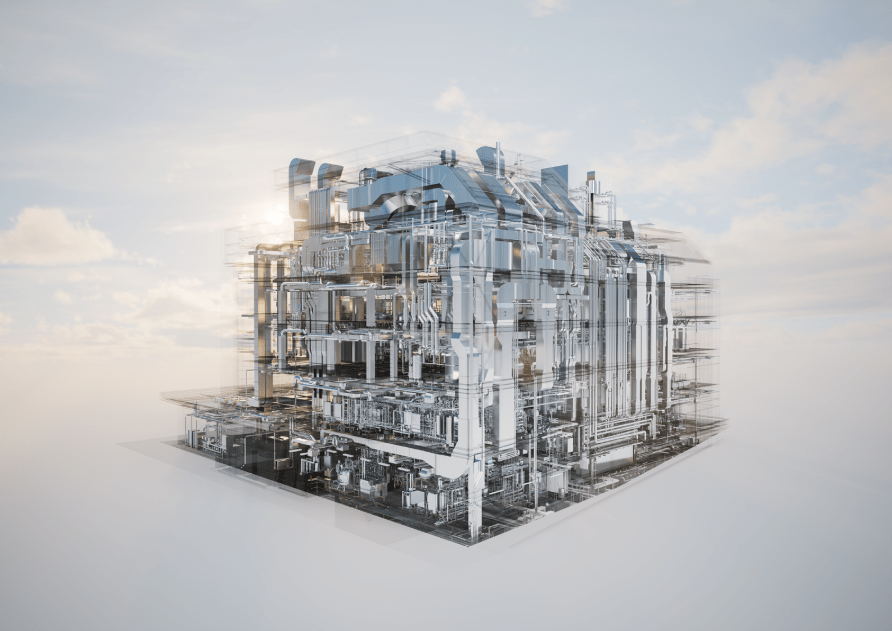

A tower fermenter (also written as fermentor) is a tall, cylindrical fermentation vessel—a type of bioreactor—with a higher height-to-diameter ratio than a conventional stirred-tank. Many tower fermenters operate as gas-driven systems (often related to bubble columns or airlift designs), where sterile air or another gas is supplied through the base and rising air bubbles drive circulation, gas–liquid mass transfer, and (to some extent) mixing.

It’s important to note that “tower fermenter” describes the geometry and format more than a single fixed internal design. In practice, tower fermenters are typically one of these different types:

- Simple tower fermenter (bubble-column tower): gas is sparged at the base and rises unidirectionally; mixing and oxygen transfer are driven by the bubbles.

- Airlift tower fermenter: a refined bubble-column design that forces a defined circulation loop using a draft tube (internal) or an external loop, creating a riser and downcomer.

- Hybrid/assisted towers (process-dependent): some tower units include limited mechanical agitation or internals to improve circulation or manage higher viscosity.

- Packed/immobilised variants (process-dependent): in some designs, cells can be immobilised cells on packing (a packed bed style), effectively combining tower geometry with immobilisation to support specific biochemical conversions.

The tower format is often chosen because it can deliver strong gas–liquid contacting with fewer moving parts than a fully agitated stirred fermenter having the aspect ratio of a standard stirred tank.

How a tower fermenter works

Tower fermenters look simple, but performance is driven by the same fundamentals as any aerobic fermenter: oxygen transfer, mixing, heat-removal, and stable control. Because the system may be tall enough to develop top-to-bottom gradients, design and operation focus on keeping conditions uniform throughout the reactor.

Aeration at the base and unidirectional gas flow

Gas is introduced near the bottom of the column via a sparger or gas distributor—often described as a sparger at the base. In aerobic runs, humid sterile air was supplied (process-dependent) to maintain culture conditions while reducing drying of the broth and filters.

In a tall vessel, bubbles have a longer distance to travel. That increases bubble residence time and can improve gas–liquid contact. It also creates a largely unidirectional flow of gases (upwards) through the liquid phase, which is one reason tower geometry can support high aeration rates.

Gas-driven circulation, zones, and mixing behaviour

As bubbles rise, they create an upward-moving two-phase region (gas + liquid), while liquid returns downward along the wall (bubble column behaviour). In airlift designs, the draft tube shapes circulation into a defined riser and downcomer, helping reduce dead zones.

This circulation mixes nutrients and distributes heat through the broth. However, mixing intensity is tied to gas rate and broth properties: if viscosity rises, solids build, or foaming increases, circulation can weaken and gradients can appear. In extreme cases, solids can begin to settle, particularly in the lower zone, which is why tower fermenters are generally best suited to broths that remain within a manageable viscosity window.

Oxygen transfer and CO₂ stripping

For aerobic fermentation, oxygen transfer is often the limiting factor. In tower fermenters, oxygen transfer depends on:

- Gas flow and gas composition (air vs oxygen enrichment)

- Bubble size distribution (sparger choice and fouling behaviour)

- Broth properties (viscosity, surface tension, biomass)

- Operating pressure and pressure drop along the height

At the same time, the gas stream can strip CO₂ from the broth, which can benefit certain organisms by improving dissolved gas balance. The trade-off is that higher gas rates can increase foam and off-gas handling demand.

Temperature control and heat-removal

Fermentation is often exothermic. In a tower fermenter, temperature control may use an external cooling jacket, internal coil, or an external heat-exchanger loop with a circulation pump (process-dependent). Because there is limited (or no) mechanical stir capability to “boost mixing” on demand, heat-transfer capacity and temperature measurement strategy must be designed carefully—especially at larger scale.

Key building blocks of a tower fermenter

A tower fermenter’s performance is shaped less by one headline feature and more by how well the system is integrated.

Vessel geometry and materials

Tower vessels are typically stainless steel at industrial scale, with hygienic finishes and cleanable geometries. Height-to-diameter ratio affects circulation and contact time; diameter affects gas holdup and how bubbles distribute across the cross-section.

In highly complex programmes, small geometry choices matter: nozzle layout, drainability, and internal weld quality all affect clean-in-place/sterilisation-in-place effectiveness and long-term reliability.

Gas distribution: spargers, perforated plates, and dispersion

The sparger is central because it sets initial bubble formation and distribution. Depending on the process and scale, designers may use different sparger types (rings, plates, porous distributors) and, in some towers, perforated plates (tray-style internals) to break up coalesced bubbles, stabilise bubble patterns, or distribute gas across the column.

The goal is not simply “more gas” but efficient dispersion: good gas distribution supports oxygen transfer while reducing local high-gas zones that can trigger foam or unstable control.

Circulation internals (airlift designs)

If the process needs more predictable circulation than a basic bubble column can deliver, airlift towers use draft tubes or external loops. These features can improve uniformity and reduce dead zones, but they add constraints around cleanability, sterilisation, and scale-up.

Off-gas handling and foam management

Tower fermenters can run at high gas rates, so off-gas capacity is a core design element. A practical set-up often includes:

- Sterile exhaust filtration

- Condensate handling to protect filters

- Pressure control (process-dependent)

- Foam detection and response strategy

Foam management is not just about avoiding overflow: persistent foam can change mass transfer, reduce effective headspace, and drive unstable operation.

Instrumentation, monitoring, and control strategy

Tower fermenters are sensitive to gradients, so instrumentation placement matters. Typical monitoring includes temperature, pH, dissolved oxygen (where applicable), gas flow, and pressure. In taller vessels, multi-point measurement can be justified to confirm the process parameter profile is stable from bottom to top.

Where tower fermenters are used

Tower fermenters are used when their geometry and gas-driven operation match the process window.

- Industrial aerobic microbial fermentation (process-dependent): when oxygen transfer is critical and broth viscosity remains manageable.

- Used for the production of organic acids (process-dependent): tower-style aerated fermenters can be used for products such as citric acid in certain submerged fermentation routes, where oxygen supply and heat removal are key constraints.

- Enzyme and antibiotic production (process-dependent): many microbial processes benefit from predictable aeration and robust operation, provided the broth does not become too viscous.

- Used for continuous culture (process-dependent): tower units can be configured for continuous operation when the biology and sterility framework support long-run stability.

- Fermentation and biological wastewater treatment: gas-driven tower formats appear in some wastewater systems because continuous aeration and robust construction match the operational reality.

A note on beverage examples: the word “tower fermenter” is sometimes used informally for tall vertical vessels in industries like vinegar fermentation and even beer production. In those cases, the vessel geometry may be tall and cylindrical, but the process needs (and the reactor internals) can be very different from an aerated tower fermenter used for aerobic microbial production.

Advantages for customers

A well-engineered tower fermenter can offer practical benefits that show up in day-to-day operation:

- Footprint efficiency: more working volume in a smaller floor area.

- Reliable operation with fewer moving parts: many tower formats avoid internal agitators and mechanical seals, reducing maintenance points.

- Solution-oriented oxygen transfer: height and gas residence time can support strong gas–liquid contact for aerobic processes.

- Tailor-made circulation options: bubble column simplicity or airlift circulation, depending on how demanding the broth is.

- Potential efficiency gains (process-dependent): for some processes, gas-driven mixing can reduce mechanical power demand compared with high-agitation stirred tanks.

Limitations and trade-offs to plan for

Tower fermenters perform best within a defined window. Outside that window, the issues tend to be structural rather than “tuning” problems.

- Gradients risk: tall vessels can develop temperature, dissolved oxygen, and concentration gradients if circulation weakens.

- Foam and off-gas load: high gas rates increase foaming risk and exhaust handling demand.

- Viscosity sensitivity: as broth viscosity rises, bubble-driven mixing can become less effective.

- Heat-removal constraints: without mechanical agitation, heat-transfer and sensor placement must be engineered for worst-case heat-load.

- Scale-up complexity: changing column diameter and height changes hydrodynamics, gas holdup, and mass-transfer behaviour; scale-up should be validated with process data, not assumptions.

These trade-offs are manageable when they are addressed early in the specification, rather than treated as operational surprises.

How to choose the right tower fermenter

A process-led selection is the most reliable way to avoid downstream rework.

Start with organism and broth behaviour

Define viscosity range, solids content, and foaming tendency across the run. If broth behaviour changes dramatically during growth or feeding, validate circulation and gradient risk early.

Define oxygen demand and mass-transfer headroom

For aerobic processes, estimate peak oxygen demand (often late growth). Then confirm whether the tower format can meet oxygen transfer targets using:

- Air only

- Oxygen enrichment

- Pressure strategy (process-dependent)

Build in headroom so the system can handle real variability, not just the average run.

Choose bubble column vs airlift

- Choose a bubble column tower when the broth is low-to-moderate viscosity and simplicity is a priority.

- Choose an airlift tower when you need more predictable circulation and better control over dead zones without moving to a fully agitated system.

Engineer foam and off-gas handling from day one

Foam strategy (headspace, foam detection, antifoam dosing logic) and exhaust capacity should be sized for worst-case gas rate. Under-designed off-gas handling is one of the fastest ways to create chronic stability issues.

Specify heat-transfer and instrumentation for stability

Size jackets/coils for worst-case heat-load and place sensors so they represent true bulk behaviour. In tall vessels, consider whether multi-point measurement is justified to detect gradients early.

Align upstream with downstream and utilities

Gas rate, antifoam use, and by-product profiles can influence downstream filtration, clarification, and product stability. Confirm utilities (compressed air, oxygen supply where used, cooling capacity) for peak load rather than average operation.

Conclusion

A tower fermenter is a tall, high-aspect-ratio fermentation vessel—often a bubble column or airlift design—that uses gas-driven circulation and height to support oxygen transfer and mixing. It can be a reliable, solution-oriented choice when footprint, mechanical simplicity, and aerobic mass-transfer needs are key drivers, and when broth behaviour remains within a manageable window. The best results come from a tailor-made specification that plans for gradients, foam, off-gas load, and heat-removal at worst-case conditions. When process and design are aligned, tower fermenters can deliver consistent performance at scale without unnecessary mechanical complexity.