ZETA Magnetic Agitators: A Versatile, Proven Product Family

At the core of ZETA’s offering is an impressive portfolio of magnetic agitators, including bottom-mounted, top-mounted, and side-entry models, each purpose-built to enhance mixing performance for pharmaceutical and biotechnology production. Our customers enjoy the best of both worlds – an established product portfolio as well as customised solutions.

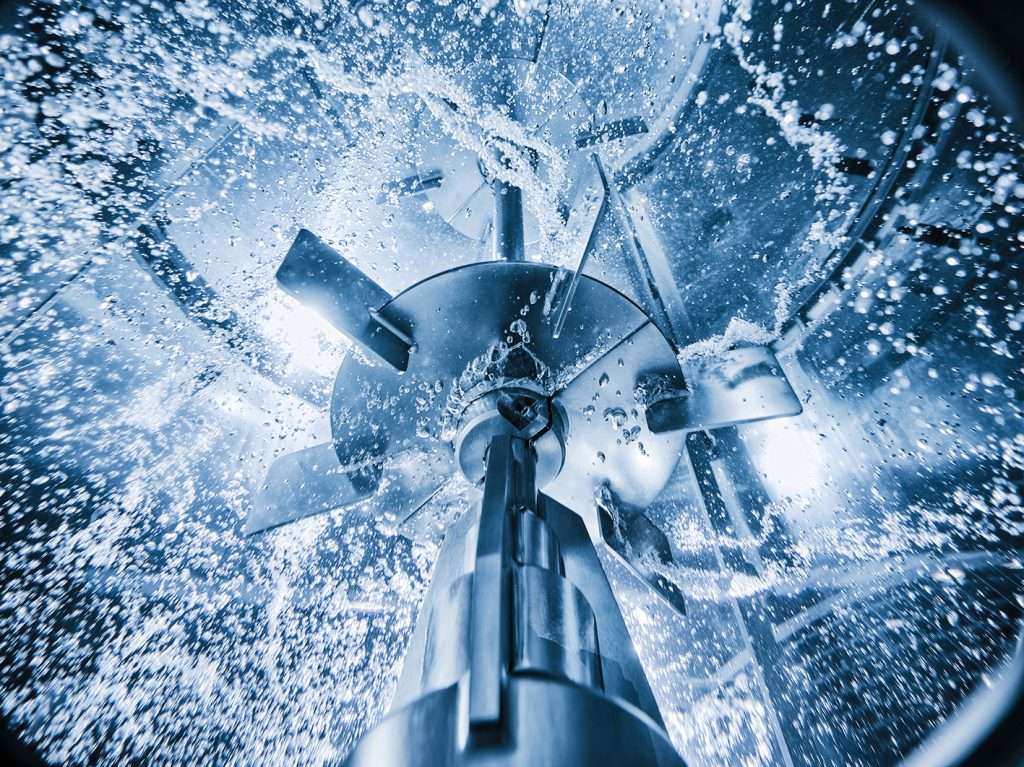

Bottom-Mounted Magnetic Agitators

State-of-the-art for low-viscosity liquids in the pharmaceutical and biotech industries, these units excel in even the most demanding agitating tasks. Especially in bioreactors of up to 30,000 litres, ZETA’s bottom-mounted designs guarantee safe, long-term process control, freeing up valuable tank lid space for sensors, valves, and sight glasses. The BMRF series, tailored for both bacterial fermentation and mammalian cell culture, leverages multiple, application-specific impeller designs. The BMRT range brings magnetic impeller technology with run-dry capability to a wide array of hygienic and sterile process tanks, while ZETA’s high-speed and high-shear mixers tackle challenging emulsion and suspension tasks with precision.

Top-Mounted and Side-Entry Agitators

ZETA has engineered top-mounted systems for critical large-vessel applications, such as 12,000L glucose mixing tanks, offering both internally mounted (AMRi series) and externally mounted (AMRe series) magnetic couplings. These designs ensure high stability, optimal for vessels with inclined shafts and demanding geometries. For even greater flexibility, side-entry agitators are available, providing customised configurations that address unique process or installation challenges.

Key Product Features & Innovations

ZETA agitators feature key components, including weld-in flanges for aseptic safety, impeller RPM monitoring for process confidence, patented bearing bush systems, extractor tools for easy containment shell removal, and versatile gear motor configurations (available in stainless steel and Ex zones). Every detail is driven by a deep understanding of the process and a relentless focus on hygienic design.

Why Pharmaceutical Leaders Choose ZETA

The products themselves are the starting point. But their value is supercharged by ZETA’s relentless commitment to both compliance and practical application.

- Hygienic, Contamination-Free Mixing

ZETA’s magnetic technology means the drive force is transmitted by magnetic fields with no physical contact between the motor and the vessel’s sterile interior. This virtually eliminates contamination risks, simplifies automation, reduces downtime, and cuts operational costs. - Regulatory, QA, and Project Support

Full GMP and sterile manufacturing compliance are built into every product. With thorough documentation, quality assurance protocols, and validation support, ZETA agitators are engineered for seamless audit-readiness, accelerating approval and startup timelines for new lines or facilities. - Customisation and Scale

ZETA balances a robust, standardised portfolio with highly customised solutions for special or complex mixing needs, continually pushed forward by ongoing R&D and process engineering expertise.

Lifecycle Partnership and After-Sales Service

ZETA’s engagement doesn’t end at commissioning. Customers enjoy comprehensive lifecycle support unique in the industry.

- Retrofits & Upgrades: ZETA can modernise existing plants by replacing outdated, mechanically sealed agitators with its magnetic, GMP-compliant technology, ensuring state-of-the-art performance across your asset base.

- Mixing Studies & Technical Consulting: With in-house bioreactor characterisation, kLa and CFD studies, and options for dismantling and installation support, ZETA’s TechCenter equips clients with the guidance needed for process optimisation and regulatory success.

- Maintenance & Spares: Rapid local service, preventive maintenance programs, and a robust inventory of spare parts guarantee minimal downtime and security for your CapEx investment.

- Training & Digitalisation: ZETA provides training for maintenance staff, and supports digital solutions for process monitoring and automation—future-proofing your facility for years to come.

Selecting ZETA: Meeting Every Pharma Procurement and Project Criterion

ZETA understands that pharma companies demand more than technical excellence. They require partners that can ensure compliance, streamline documentation, deliver on time, and back their products with world-class project management and after-sales support. With proven references in high-profile installations, flexible solutions for scale-up, and a passion for solving clients’ unique process challenges, ZETA stands as the partner of choice across the biopharma sector.

Experience the Next Generation of Aseptic Mixing – Partner with ZETA

From the first technical consultation to hassle-free long-term operation, ZETA magnetic agitators are not just an equipment investment, but a foundation for compliant, cost-effective, and high-performing pharmaceutical production.